오늘날의 산업 제조 분야에서 레이저 기술은 의심할 여지 없이 빛나는 별이 되었습니다. 특히 절단 공정에서 레이저 절단기는 높은 정밀도, 고효율 및 높은 유연성이라는 장점으로 인해 많은 회사에서 첫 번째 선택이 되었습니다. 레이저 절단 기술의 세분화로서 레이저 튜브 절단기는 튜브 가공 분야에서 빛을 발했습니다. 오늘은 이 마법같은 레이저 세계로 들어가 레이저 절단 및 레이저 튜브 절단 기계의 원리와 응용을 살펴보겠습니다.

레이저 절단기: 정밀 절단

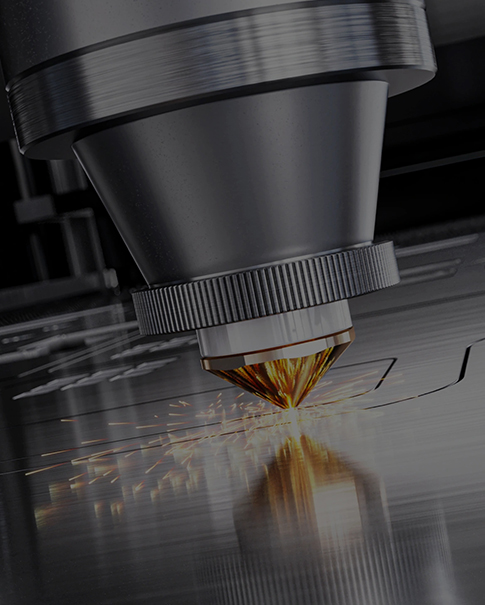

파이버 레이저 절단기의 원리는 간단해 보이지만 심오한 기술적 의미를 담고 있습니다. 레이저는 핵심 부품으로 특수한 물리적 메커니즘을 통해 고강도 레이저 빔을 생성합니다. 이 빛의 광선은 광섬유를 통해 레이저 헤드로 전송되어 매우 작은 지점에 초점이 맞춰집니다. 이 지점을 가공물의 표면에 조사하면 레이저의 높은 에너지 밀도로 인해 조사된 재료가 빠르게 녹아 기화됩니다. 동시에, 빔과 동축인 고속 기류는 용융된 재료를 날려버리고 명확한 절개부를 형성합니다.

레이저 절단기의 가장 큰 장점은 높은 정밀도와 유연성입니다. CNC 시스템의 정밀한 제어를 통해 레이저 헤드는 복잡한 궤적을 따라 이동하여 다양한 모양의 절단을 달성할 수 있습니다. 직선이든 곡선이든 특수 형상의 공작물이든 레이저 절단기는 쉽게 처리할 수 있습니다. 또한 레이저 절단은 열 영향 영역이 작고 절단 표면이 매끄러워 가공 품질과 효율성이 크게 향상된다는 장점도 있습니다.

레이저 튜브 절단기: 튜브 가공을 위한 날카로운 도구

T우베 laser 절단기는 튜브 가공 분야에 레이저 절단 기술을 적용한 것입니다. 작동 원리는 레이저 절단기와 유사하지만 튜브의 특성에 최적화되어 있습니다. 튜브 레이저 절단기는 일반적으로 척으로 튜브를 고정하고 피드 회전 동작과 절단 헤드의 상하 좌우 동작을 통해 보간 동작을 형성하여 튜브의 절단 궤적을 달성합니다.

T우베 laser 절단기에는 다양한 응용 분야가 있습니다. 원형 튜브, 사각 튜브, 타원형 튜브 또는 C자형 튜브뿐만 아니라 앵글강, 채널강, H형강 등과 같은 다중 금속 튜브이든 튜브 레이저 절단기는 효율적이고 정밀한 작업을 수행할 수 있습니다. 처리. 특히 복잡한 모양의 튜브 가공에서 튜브 레이저 절단기는 독특한 장점을 보여주었습니다. CNC 시스템의 프로그래밍을 통해 다양하고 복잡한 절단 궤적을 쉽게 실현하여 고객의 맞춤형 요구 사항을 충족할 수 있습니다.

과학과 기술이 지속적으로 발전함에 따라 레이저 기술은 더 많은 분야에 적용될 것입니다. 절단 기술 측면에서 레이저 절단기는 고정밀, 고효율 및 고도 자동화 방향으로 계속 발전할 것입니다. 동시에 새로운 재료가 지속적으로 등장함에 따라 레이저 절단 기계는 더 많은 도전과 기회에 직면하게 될 것입니다. 레이저 절단 기술의 중요한 분야인 레이저 튜브 절단기는 튜브 가공 분야에서도 더 큰 역할을 할 것입니다.

간단히 말해서, 레이저 절단 및 레이저 튜브 절단 기계는 고유한 장점으로 인해 산업 제조 분야에서 점점 더 중요한 역할을 하고 있습니다. 나는 가까운 미래에 레이저 기술이 우리에게 더 많은 놀라움과 가능성을 가져다 줄 것이라고 믿습니다.